X's-BT Series

Battery Inspection Systems

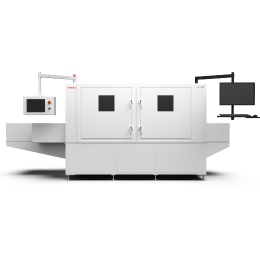

In-line X's-BT series

| Applications | Secondary battery (lithium-ion battery) |

|---|

Supports various external shapes and internal structures such as cylindrical batteries (2170, 1865, 4680, Coin Type), laminate batteries (winding, laminating), and prismatic batteries.

FEATURES

X's-BT series: Battery inspection systems

Defects such as electrode misalignment, component positions, and foreign matter inside the battery are automatically measured by image processing and sorted into good and defective products by X-ray inspection.

Batteries are taken in from upstream of the production line, inspected, and passed downstream according to the automatic judgment results.

・The system can handle a variety of products, mainly lithium-ion batteries (cylindrical, coin, laminated, and rectangular types)

・Dimensional control and feature extraction of the inspected area are possible

・High-speed inspection tact time to match the speed of the production line (high-speed inspection in less than 1 second/cell is possible depending on the shape)

・Proposal of sorting method for good/defective products is also possible according to the production line

・Fluoroscopy images and measurement results can be logged for easy identification of statistics and trends by lot or date of manufacture

・Proven track record in Japan and overseas

CASE EXAMPLE

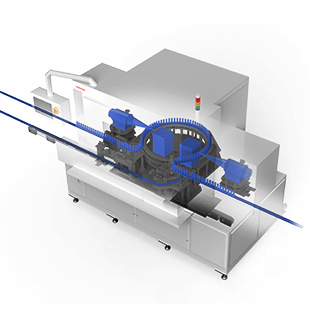

Cylindrical lithium-ion rechargeable battery

In-line inspection system dedicated to cylindrical batteries (2170, 1865, 4680, etc.).

・Customized inspection items are available

・Winding misalignment, center pin inspection, foreign matter inspection, etc

・Cell transport configuration is on request

Inside of battery inspection system

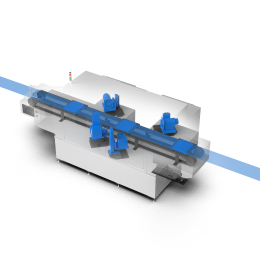

Laminate type lithium-ion rechargeable battery (stacked type)

In-line inspection system exclusively for batteries whose outer packaging is covered with laminated film.

・Tabs can be positioned on either one or both sides

・Not only lamination misalignment, but also rotational misalignment inspection is available

・Inspection process is discussed upon request

Other application example

We have a large number of experience in inspection of welds, contamination inside electrodes, internal structural defects, etc.