X-Ray Nondestructive Inspection System

High definition Micro Focus CT Scanner

TXS-33000FD/32300FD

| Applications | Aluminum die castings, batteries, small electronic components, chip mounted boards, molded components, resins, fibers, etc. |

|---|

This CT scanner has excellent versatility with high image contrast in entire X-ray energy range can achieve both fluoroscopic image and CT image in wide dynamic range. Various kinds of application from quality control to precise analysis are possible.

FEATURES

High versatility CT scanner

300kV/230kV type

CT scanner line-ups which has wide versatility on inspection and analysis has been provided applying from low energy range to high energy range by incorporating micro focus X-ray generator and new X-ray detector.

With the combination of X-ray generator (Maximum tube voltage 300kV/230kV) and optimized X-ray detector, 300kV model has been improved the penetration power, meanwhile, 230kV model has been realized high image quality under the low energy conditions.

High quality of CT image

By combing each X-ray generator with the best matched detector, 230kV model can be realized high image contrast and surprising image quality due to capturing soft X-ray more, on the other hand, since 300kv type has been increased penetration power in high energy range, high image quality and resolution has been realized even if the object is large size or heavy metal which is tough to penetrate.Furthermore, with the unique HDR image processing can realize high image contrast and high speed image reconstruction, high quality image can be obtained in a short time. In addition, incorporating Auto-centering and Fully auto-calibration which are important function when scanning has improved the operability. Reduction of scatter X-ray by equipping Collimator has also improved the image quality.

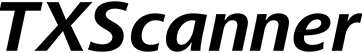

Renewal of user interface

Realized intuitive operability “Smart Mode” can perform CT scanning easily has provided.

Step1 Specifying scanning area ・・・・Outer view/Fluoroscopic image/CT image

Step2 Auto-collection of the material and search conditions by Auto-button

Step3 Selection of arbitrary image quality and scanning time

CT scanning will be executed after performing calibration of scanning position, air data collection and offset data collection by Auto-calibration function. And the sample stage can be moved to the best magnification position by Auto-scan positioning function. Conventional “Expert mode” is also provided to do CT scanning fit to the inspection purpose.

Improvement on maintenance and safety

High voltage cable has become unnecessary by adoption of all-in-one structure of high voltage generator. This structure allows you to avoid from troublesome grease up work.

The trouble of cable breaking caused by electric discharge occurred inside of X-ray tube is gone away.Furthermore, there is no high voltage generator outside of the machine cabinet can be safely.

With adopting “Click cathode method” in exchanging the filament can make easier the exchanging work (Axis adjusting work is no needed.)

Sample door has duplicated safety system consists of electro-magnetic lock and X-ray inter lock system. In addition, the prevention function from pinch by closing door is also equipped.

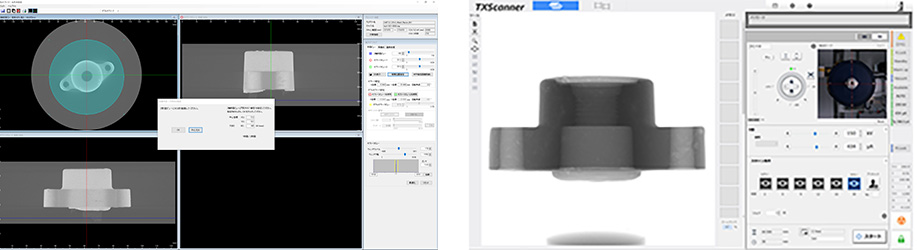

IMAGE EXAMPLES

SPECIFICATION

| Key specification | ||

|---|---|---|

| Model | TXS-33000FD | TXS-32300FD |

| X-ray generator | 300kV | 230kV |

| Minimum X-ray focal spot size | 4μm | |

| X-ray detector | FPD (Flat Panel Detector) | |

| Maximum sample size | Φ420×H450mm | |

| Maximum scan area | Φ420×H320mm | |

| Maximum sample weight | 20kg | |

| X-ray generator | 230kV |

|---|---|

| Minimum X-ray focal spot size | 4μm |

| X-ray detector | FPD (Flat Panel Detector) 8" / 16" |

| Maximum sample size / weight | Φ420×H450mm/20Kg |

| Maximum scan area | Φ420×H320mm(16-inch) |

| External dimensions | W2380×D1670×H1800mm |

| Main unit weight | Approx. 4000Kg |

| Power supply / ground | Single-phase AC 100V, 4kVA / Earth resistance: 100Ω or less |

| X-ray generator | 300kV |

|---|---|

| Minimum X-ray focal spot size | 4μm |

| X-ray detector | FPD (Flat Panel Detector) 8" / 16" |

| Maximum sample size / weight | Φ420×H450mm/20Kg |

| Maximum scan area | Φ420×H320mm(8-inch/16-inch) |

| External dimensions | W2380×D1670×H1805mm |

| Main unit weight | Approx. 4800Kg |

| Power supply / ground | Single-phase AC 100V, 4kVA / Earth resistance: 100Ω or less |

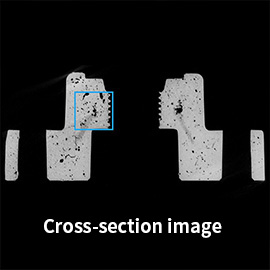

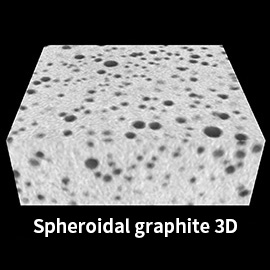

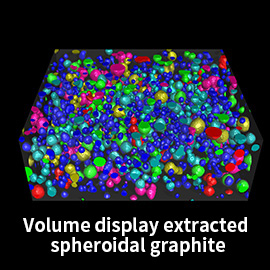

CASE EXAMPLE

Analysis for Die casting parts

・Porosity analysis

The cavity extracted automatically can be classified and color-coded in several hundred micro millimeter unit by the volume. The distribution of the cavity can be seen as 3D display.

・Comparison with design value

Matching nominal 3D CAD data with actual CT data, the measurement error can be seen and classified by color-coded.

Porosity analysis for aluminum die casting

Comparison CT data with 3D CAD (aluminum die casting)