X-Ray Nondestructive Inspection System

Micro-focus TXView

| Applications | Chip mounted boards, electronic devices, small connectors, small automotive electronic parts, etc. |

|---|

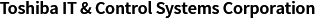

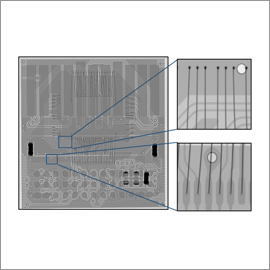

With the TXView micro-focus X-ray inspection system, you can analyze the internal conditions of small precision parts, electronic devices, and other components.

FEATURES

Micro-focus X-ray generator and a flat panel detector (FPD)

Select from 90-kV or 130-kV X-ray generators.

The 1.3-megapixel FPD provides clear images without distortion.

Functions for various types of analysis

The new TXView incorporates a proprietary high-dynamic-range (HDR) function to improve image quality and thus provides clearer images than the previous model.

The optional vertical CT unit makes 3D analysis possible.

Improved operability

The integrated camera for capturing the external appearance of an object makes it possible to operate the CT scanner while viewing a sample, enhancing operability.

The guided operation mode and improved software make it easy to capture clear images.

Ergonomic design

With its ergonomic design, the TXView is easy to use, regardless of whether you are sitting or standing.

As a result of improvements to the opening and angle of the sample door, the TXView now provides even better usability.

IMAGE EXAMPLES

SPECIFICATION

| Key Specifications | ||

|---|---|---|

| Model | TXV-S4130FD | TXV-S4090FD |

| X-ray output | 130kV / 300μA | 90kV / 200μA |

| Minimum X-ray focal spot size | 5μm | |

| X-ray detector | 1.3-megapixel flat panel detector (FPD) | |

| Spatial resolution | 5μm(JIMA RT RC-05) | |

| On-monitor magnification | ×160 (24-inch monitor) | ×210 (24-inch monitor) |

| Maximum external dimensions of the sample table | 410×360×80 mm | |

| Maximum sample weight | 2kg | |

| X-ray output | 90kV/200μA |

|---|---|

| Minimum X-ray focal spot size | 5μm |

| X-ray detector | 1.3-megapixel flat panel detector (FPD) |

| Spatial resolution | 5μm(JIMA RT RC-05) |

| On-monitor magnification | ×210 (24-inch monitor) |

| Maximum external dimensions of the sample table | 410×360×80 mm |

| Maximum sample weight | 2kg |

| Main unit external dimensions (W×D×H) | 1150×1105×1725 mm |

| Main unit weight | Approx. 950kg |

| Leakage dose | 1 μSv/h or less |

| Power supply / ground | Single-phase 100 VAC, 1.5 kVA / Earth resistance: 100 Ω or less |

| X-ray output | 130kV/300μA |

|---|---|

| Minimum X-ray focal spot size | 5μm |

| X-ray detector | 1.3-megapixel flat panel detector (FPD)/td> |

| Spatial resolution | 5μm(JIMA RT RC-05) |

| On-monitor magnification | ×160 (24-inch monitor) |

| Maximum external dimensions of the sample table | 410×360×80 mm |

| Maximum sample weight | 2kg |

| Main unit external dimensions (W×D×H) | 1150×1105×1725 mm |

| Main unit weight | Approx. 1100 kg |

| Leakage dose | 1 μSv/h or less |

| Power supply / ground | Single-phase 100 VAC, 1.5 kVA / Earth resistance: 100 Ω or less |

| Image analysis and measurement functions | |

|---|---|

| Measurement functions | Wettability, wire sweep, point-to-point distance, BGA void calculation |

| Analysis functions | Pseudo-color images, profiles, histograms, 3D rendering |

| Options | |

|---|---|

| Vertical CT (cone beam CT) | Vertical CT unit (attachable) |

| Two-axis rotating gear | Rotating and tilting gear (attachable) |

CASE EXAMPLE

Vertical CT (capacitor)

The following videos show the images of a capacitor using the optional vertical (cone beam) CT unit.

The cross-sectional images of a capacitor can be used to observe and analyze internal contaminants and flaws in 3D.

Capacitor (horizontal cross section)

Capacitor (vertical cross section)