TOSCANER-20000/30000 Series

X-Ray Nondestructive Inspection Systems

High Energy CT Scanner TOSCANER-24500twin/AV TOSCANER-34500FD

| Applications | Large aluminum die castings, iron, castings, cylinders, tires, engine blocks, etc. |

|---|

20000 series is equipped with a line sensor as the X-ray detector, and can shoot high-quality images even for large aluminum die-cast products, castings, tires, and other products with severe X-ray transmission.

30000 series is equipped with an FPD and can capture up to 1024 slices of CT images in a single scan.

FEATURES

450kV High Energy CT Scanner

The high-energy X-ray generator with a maximum tube voltage of 450 kV enables CT imaging of large parts and heavy metal products with severe X-ray transmission.

Two models with different detectors

Line sensor (LDA) type: The TR (Translate / Rotate) method enables you to shoot high-quality continuous cross sections at twice or three times the speed of conventional models. (Fastest 10 seconds / slice)

Equipped with various scan modes: half / full / double full, etc.

Flat panel (FPD) type: The combination of RO (rotate only) method and FPD allows you to capture up to 1,024 images in a single scan. (Fastest 30 seconds / scan)

You can specify the slice position from the real-time fluoroscopic image and take a CT image.

Composite CT can also be proposed

Some CTs are equipped with both LDA and FPD detectors and can perform high-quality / high-speed scanning with one unit.

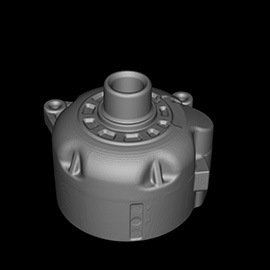

IMAGE EXAMPLES

SPECIFICATION

| Key Specifications | |||

|---|---|---|---|

| Model | TOSCANER-24500twin | TOSCANER-24500AV | TOSCANER-34500FD |

| X-ray generator | 430kV | ||

| Focal spot size | 04/1.0mm selectable | ||

| Detector | Line sensor (twin) | Line sensor | FPD※(16-inch) |

| Spatial resolution | 0.1mm | ||

| Scanning method | Translate/Rotate | Rotate only | |

| Maximum scan area | Standard:φ600×H600mm Option:φ700×H1000mm |

φ600×H600mm | |

| Option | UPS / Digital engeneering / PC for image processing |

UPS / Digital engeneering / PC for image processing / High speed reconstruction |

|

| Lakage dose | Less than 2μSv/h | ||

| Application | Concrete,medium or large sized aluminum die cast,Iron parts,Casting etc | ||

* FPD: Flat Panel Detector

| X-ray generator | 450kV |

|---|---|

| Maximum sample size | φ600×H600 mm |

| Penetration length | Aluminum: 300 mm Iron: 100 mm |

| Minimum scan time | 30 seconds |

| Scan mode | Translate-rotate (TR) scan |

| X-ray generator | 450kV |

|---|---|

| Maximum sample size | φ600×H600 mm |

| Penetration length | Aluminum: 300 mm Iron: 100 mm |

| Minimum scan time | Single-scan: 30 seconds Twin-scan: 15 seconds Triple-scan: 10 seconds |

| Scan mode | Translate-rotate (TR) scan |

| X-ray generator | 450kV |

|---|---|

| Maximum sample size | φ450×H500 mm |

| Penetration length | Aluminum: 300 mm Iron: 100 mm |

| Minimum scan time | Single-scan: 30 seconds Twin-scan: 15 seconds Triple-scan: 10 seconds |

| Scan mode | Translate-rotate (TR) scan |

| X-ray generator | 450kV |

|---|---|

| Maximum sample size | φ700×H1000 mm |

| Penetration length | Aluminum: 300 mm Iron: 100 mm |

| Minimum scan time | Single-scan: 30 seconds Twin-scan: 15 seconds Triple-scan: 10 seconds |

| Scan mode | Translate-rotate (TR) scan |

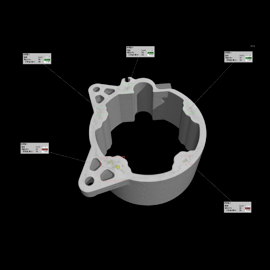

CASE EXAMPLE

Analysis (measurement) of a large aluminum die-cast workpiece

The following video compares the dimensions of a design drawing and the X-ray scanned image of a die-cast workpiece.

The TOSCANER-20000 series can use an X-ray image to measure external and internal dimensions that are difficult to measure using other methods.

Differences between design and actual dimensions are color-coded to simplify comparison analyses.

Comparison of design and actual dimensions